Flyability ELIOS Drone

Who is Flyability?

Flyability is a Swiss company based in Lausanne that specializes in building safe drones for operating indoors, in complex, and confined spaces. The company was founded in 2014 by Patrick Thévoz and Adrien Briod, who were studying robotics at the École Polytechnique Fédérale de Lausanne (EPFL) at the time. Their goal was to create drones that could be used to safely and efficiently perform inspections in hazardous environments, such as power plants, oil and gas facilities, and mines.

Flyability has received numerous awards for its technology, including the USD 1m UAE Drones for Good award. The company has over 100 employees and has raised USD 27m to date. It targets revenues of USD 20m in 2022 and currently has over 800 customers worldwide.

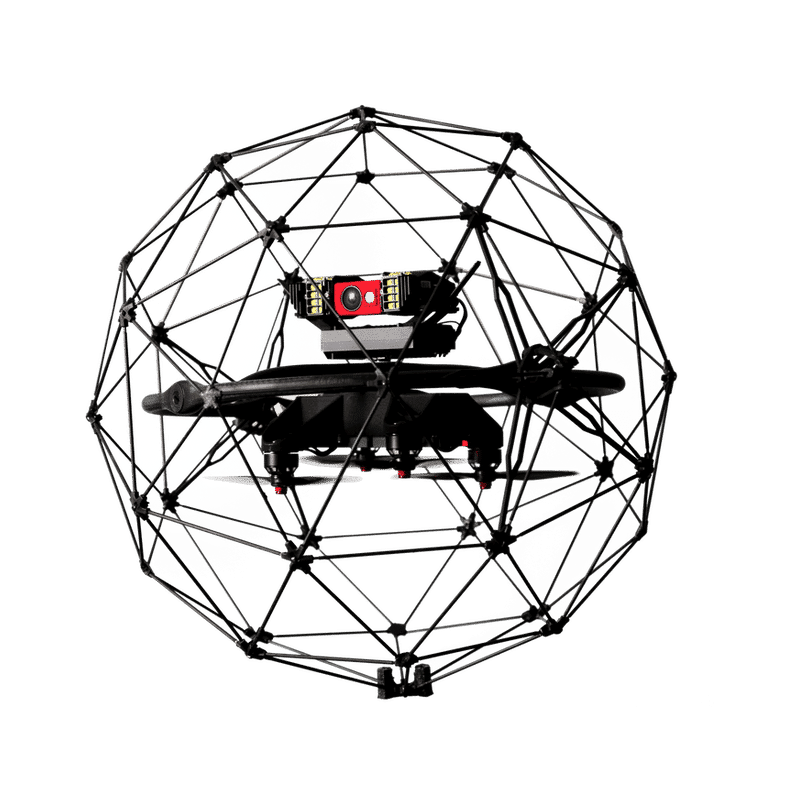

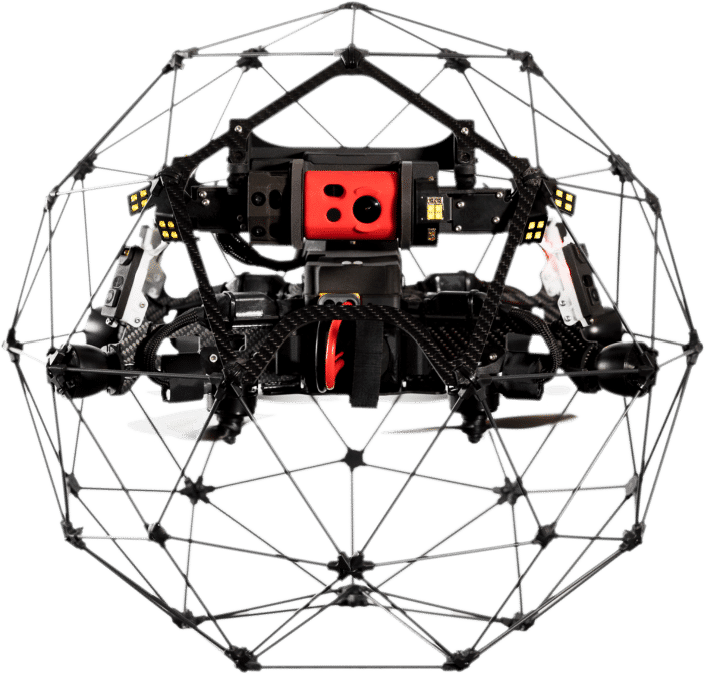

The company’s drones are designed to operate in challenging environments, navigating

through obstacles, complex environments, and collisions. One of the major features of Flyability’s drones is their collision tolerance. The drones are protected by a carbon-fiber cage that provides the first level of protection. The second level of protection is based on algorithms and sensors that enable the drone to understand its trajectory and location. These drones can operate in very dark, dusty, complex, and GPS-deprived environments.

Flyability’s mission is to remove humans from dangerous industrial jobs, which can be a major occupational hazard. The company’s drones can reduce the need for expensive access methods like scaffolding or rope access, which can cost hundreds of thousands of dollars and lead to downtime. By using drones, customers can save tens, if not hundreds, of thousands of dollars, and reduce downtime by carrying out inspections more rapidly.

Flyability’s customers include inspection companies like Bureau Veritas, DEKRA, or SGS, as well as end users and asset operators in industries like chemicals, oil and gas, power generation, cement, utilities, and mining. Some of the company’s landmark customers include Dow and BASF in the chemicals industry, BHP and Rio Tinto in mining, and Enel and EDF in the electric industry. Flyability is present at around 75% of US-based nuclear power plants and works with many of the large electric companies like Exelon, Duke Energy, and TVA.

Data is at the heart of what Flyability delivers. The drone itself is only part of the solution; it is the data acquisition vector. Live output from the drone to its operator allows them to understand where it is and spot defects. After the drone’s mission, all the data is organized and used to identify defects. It is then exported to an inspection report built by Flyability’s software or to the

software Flyability’s customers use to manage their data.

Flyability is the pioneer in the world of indoor inspection, and the company is the market leader in this field. Its biggest competitors are traditional access methods like scaffolding, rope access, and sending people into confined spaces. The company’s other competitors fit into three categories: big, well-established drone companies that focus on the outdoor market; vertically-focused inspection solutions, many of them in mining; and a few companies recently inspired by Flyability’s products, leveraging its success.

Flyability sells its products through a mix of direct and indirect channels. About 23% of its sales are direct to its key accounts, with which the company is building fleets of drones. The rest of Flyability’s sales are done through a network of around 60 resellers around the world, managed from its offices in Lausanne, Denver, and Singapore.

Some other industries that Flyability’s drones can be used in include:

- Construction: Inspecting buildings, tunnels, and bridges for structural damage, as well as conducting safety inspections of construction sites.

- Industrial plants: inspection of confined spaces in industrial plants, power plants and infrastructure.

- Emergency response: Assessing damage to buildings and infrastructure after natural disasters or accidents, as well as assisting in search and rescue missions.

Overall, the applications for Flyability’s drones are diverse and continue to expand as industries recognize the benefits of safer, more efficient, and cost-effective inspections.

Flyability ELIOS 1 Inspection Drone for Powerplants

The Flyability ELIOS 1 was the first drone developed by Flyability, a Swiss company specializing in the development of drones for industrial inspection. Like the ELIOS 2, it is designed for indoor exploration and inspection in challenging environments.

The ELIOS 1 has a unique spherical cage design that protects it from collisions with obstacles and enables it to bounce off surfaces and continue flying. The cage also protects the drone’s rotors from damage, making it a very robust and durable drone.

The ELIOS 1 is equipped with a high-resolution camera that can capture images and videos of difficult-to-reach areas. The camera is mounted on a gimbal that stabilizes the footage, ensuring that the images captured are clear and steady. The drone is also equipped with powerful lighting that illuminates dark areas and improves the visibility of the camera feed.

The ELIOS 1 has a flight time of up to 10 minutes and can operate in temperatures ranging from -10°C to 50°C. It can also fly in GPS-denied environments using its on-board sensors, which include an altimeter, accelerometer, and gyroscope.

Overall, the ELIOS 1 is a highly capable drone that is designed for use in challenging indoor environments, where its unique design and flight capabilities make it an ideal tool for industrial inspection and exploration. While the ELIOS 2 has improved on the capabilities of the ELIOS 1, the original model remains a popular and reliable drone for industrial applications.

Flyability ELIOS 2 Indoor Drone with 4k Camera

The Flyability ELIOS 2 inspection drone is a cutting-edge piece of technology designed to revolutionize the field of industrial inspections. It is a fully enclosed drone that can fly in complex indoor environments, such as power plants, oil and gas refineries, and chemical factories. The drone is equipped with a 4K camera that can capture high-quality images and videos, and its collision-tolerant design allows it to navigate through tight spaces and around obstacles with ease.

One of the primary benefits of the Flyability ELIOS 2 inspection drone is its ability to perform inspections in hazardous environments without putting human lives at risk. By using the drone to inspect equipment and infrastructure, companies can reduce the risk of accidents and ensure the safety of their employees. Additionally, the drone’s advanced imaging capabilities allow inspectors to identify potential problems before they become major issues, which can save companies time and money in the long run.

The Flyability ELIOS 2 inspection drone is also incredibly versatile. It can be used to inspect a wide range of equipment and infrastructure, including boilers, tanks, pipes, and ducts. The drone’s collision-tolerant design also allows it to fly close to structures, which can help inspectors identify small cracks or other issues that might not be visible from a distance.

Overall, the Flyability ELIOS 2 inspection drone is a game-changer for the field of industrial inspections. Its advanced technology, safety features, and versatility make it an invaluable tool for companies looking to improve their inspection processes and ensure the safety of their employees.

Flyability ELIOS 3 Industrial Inspection Drone with Lidar

The Flyability Elios 3 is a cutting-edge indoor drone designed for use in complex industrial environments. With its collision-tolerant cage and unique inverted motors, the Elios 3 is the only drone on the market that can recover from a flip without crashing. Its robust IP-44 design allows for inspection and mapping in harsh environments without concerns of water or dust damage.

The Elios 3 is the first mapping and inspection drone for indoor use that offers an unparalleled combination of intelligence, versatility, and stability. Its FlyAware technology provides centimeter-accurate indoor GPS through a combination of computer vision, LIDAR technology, and a powerful NVIDIA graphics engine. This allows the drone to instantly capture its environment and create real-time 3D maps.

The drone’s SLAM-based stabilization algorithm detects the smallest unexpected movements and instructs the flight controller to compensate for them, allowing the Elios 3 to hover steadily even under adverse conditions.

To capture data, the Elios 3 uses a LiDAR scanner that can record nearly 650,000 points per second with a maximum range of 50 meters. Integration with the GeoSLAM software suite enables the drone to create survey-grade 3D models for mapping inaccessible environments.

The Elios 3’s fixed payload has a fully unobstructed 180-degree field of view for its 4K camera, thermal camera, and distance sensor. The lighting system has been completely redesigned to provide even more powerful and homogeneous illumination. With its industry-leading slanted and dustproof lighting system, the Elios 3 makes it even easier to search for corrosion, cracks, or adhesions in hard-to-reach areas.

In summary, the Flyability Elios 3 inspection drone is a revolutionary tool for industrial inspections, enabling users to safely and easily gather accurate data in challenging indoor environments.

Flyability ELIOS Range Extender für Elios 1 and 2

The Flyability Range Extender is an accessory designed to increase the operating range of Flyability drones, including the Elios 2 and Elios 1. The range extender consists of a small device that is attached to the drone’s controller and an antenna that extends the range of the drone’s radio signal.

The range extender is designed to enable the drone to operate at greater distances from the pilot, allowing it to explore and inspect larger areas. It works by boosting the power of the radio signal sent from the drone to the controller, and vice versa, allowing the drone to maintain a strong and stable connection with the controller even at greater distances.

The Flyability Range Extender can increase the range of the drone’s radio signal by up to four times, depending on the environment in which it is being used. It is also very easy to install and use, requiring no special technical expertise or tools.

Overall, the Flyability Range Extender is a valuable accessory for Flyability drones, particularly for industrial inspection and exploration applications where the drone needs to cover large areas or operate in challenging environments with limited connectivity. By extending the range of the drone’s radio signal, the range extender improves the reliability and effectiveness of the drone in these applications.

In which industries can the Flyability Elios drone be used?

The Flyability Elios drone can be used in a wide range of industries, including:

- Oil and gas

- Power generation

- Chemicals and petrochemicals

- Mining and quarrying

- Construction and infrastructure

- Transportation and logistics

- Manufacturing

- Inspection and testing services

- Search and rescue

These industries can benefit from the use of Flyability Elios drones due to their ability to access and inspect hard-to-reach areas, improve safety, and reduce costs associated with traditional inspection methods.

In the oil and gas industry, for example, the drones can be used to inspect pipelines, tanks, and refineries for leaks, corrosion, and other damage, while in the power generation industry, the drones can be used to inspect wind turbines, solar panels, and other equipment for damage and wear.

In the chemical and petrochemical industry, the drones can be used to inspect storage tanks and processing equipment for damage and wear, while in mining and quarrying, they can be used to inspect tunnels and shafts for structural damage and geological features.

In the construction and infrastructure industry, the drones can be used to inspect roofs, facades, and ventilation systems of buildings for damage and wear, while in the transportation and logistics industry, they can be used to inspect bridges, tunnels, and other infrastructure for damage and wear.

In the manufacturing industry, the drones can be used to inspect machinery and equipment for damage and wear, while in agriculture, they can be used to monitor crop health and detect pests and diseases.

In the inspection and testing services industry, the drones can be used for a wide range of inspection and testing applications, including non-destructive testing, thermal imaging, and video inspection.

Finally, in the search and rescue industry, the drones can be used to access and inspect hard-to-reach areas in emergency situations, such as collapsed buildings or natural disasters.

Which types of installations can be inspected with Flyability ELIOS drones?

- Oil and gas facilities: Flyability Elios drones can inspect pipelines, tanks, and refineries for leaks, corrosion, and other damage without the need for scaffolding or confined space entry. The drones can access areas that are difficult or dangerous for human inspectors, such as above-ground pipelines and storage tanks.

- Nuclear power plants: Elios drones can be used to inspect reactors and other equipment in nuclear power plants. They can access areas that are difficult for human inspectors, such as the reactor pressure vessel and steam generators. The drones can also be used to inspect auxiliary equipment, such as pumps and valves, and to detect radiation hotspots.

- Chemical plants: Flyability Elios drones can inspect storage tanks and processing equipment for leaks, corrosion, and other damage. The drones can also be used to inspect hard-to-reach areas, such as vessels and pipes, without the need for scaffolding or confined space entry.

- Mines and quarries: Elios drones can be used to inspect tunnels and shafts in mines and quarries for structural damage and geological features. The drones can also be used to inspect large equipment, such as crushers and conveyors, and to monitor the progress of excavation work.

- Power generation facilities: Flyability Elios drones can inspect wind turbines and solar panels for damage and wear. The drones can access areas that are difficult for human inspectors, such as the interior of wind turbine blades. The drones can also be used to inspect other equipment, such as transformers and switchgear.

- Bridges and tunnels: Elios drones can be used to inspect structural components of bridges and tunnels, such as the underside of bridge decks and the interior of tunnels. The drones can also be used to inspect hard-to-reach areas, such as the tops of bridge towers and the sides of retaining walls.

- Buildings and infrastructure: Flyability Elios drones can inspect roofs, facades, and ventilation systems of buildings for damage and wear. The drones can also be used to inspect interior spaces, such as ductwork and elevator shafts, without the need for scaffolding or confined space entry.

- Industrial machinery and equipment: Elios drones can be used to inspect motors, pumps, and turbines for damage and wear. The drones can access areas that are difficult for human inspectors, such as the interior of machinery and equipment.

- Confined spaces: Flyability Elios drones can be used to inspect storage vessels and silos for damage and wear. The drones can access areas that are difficult for human inspectors, such as the interior of confined spaces.

- Historical and cultural sites: Elios drones can be used to inspect monuments and archaeological sites for damage and wear. The drones can access areas that are difficult for human inspectors, such as the tops of monuments and the interior of archaeological structures.

These are just a few examples of the many applications of Flyability Elios drones. The drones are highly versatile and can be used in a wide range of industries and environments to inspect assets that would otherwise be difficult or dangerous to access.

Who are Flyability's customers?

Flyability specializes in the development of drones that can be used in tight and hard-to-reach spaces. As such, its customers and target audience primarily consist of companies and organizations that work in such environments.

One important customer group is companies in the energy and utilities sector. The drones developed by Flyability can be used in oil and gas facilities, power plants, or wind farms to perform inspections or make maintenance work easier.

The industrial and construction industry, as well as the transportation and logistics sector, are also among the target audience of Flyability. The drones can be used, for example, in factories, warehouses, or tunnels to perform inspections or monitor the condition of equipment and infrastructure.

Furthermore, rescue services and security forces can also benefit from the drones developed by Flyability. They can be used to support search and rescue operations or monitor dangerous situations.

In addition to these customer groups, certification agencies and inspection services are also customers of Flyability. They can use the drones to perform inspections and audits in areas that are difficult to access.

Overall, Flyability targets companies and organizations that are looking for effective and safe solutions for the use of drones in challenging environments.

Flyability drone design and technology

Flyability’s drones are revolutionizing various industries by providing cost-effective solutions for inspections and maintenance. The use of drones has proven to be a game-changer for many companies, resulting in significant savings for their customers.

One of the main benefits of using Flyability’s drones is the reduced cost of inspections. Traditional inspection methods often require expensive equipment, specialized personnel, and lengthy downtimes. Flyability’s drones, however, can carry out inspections safely and efficiently, reducing inspection costs by up to 50%. This translates into significant savings for customers who can redirect these funds to other areas of their business.

In the energy sector, Flyability’s drones have been used to inspect wind turbines, reducing inspection costs by up to 30%. The drones can access hard-to-reach areas, allowing for a more thorough inspection and identification of potential issues. In the oil and gas industry, drones have been used to inspect pipelines and offshore platforms, saving up to 70% of the costs associated with traditional inspection methods.

The use of drones in the construction industry has also resulted in significant savings. Flyability’s drones can inspect building facades, bridges, and other structures, reducing inspection costs by up to 50%. This has led to improved safety, as drones can access areas that are too dangerous or difficult for humans to reach.

Overall, Flyability’s drones have proven to be a cost-effective solution for various industries, resulting in significant savings for their customers. Businesses can now benefit from the use of drones, not only in terms of improved efficiency and safety but also in terms of reduced costs.

Differentiating Features of Flyability Compared to Competition

Flyability has played a pioneering role in the development of indoor drones, setting it apart from its competitors. When comparing Flyability with other inspection methods such as scaffolding or rope access, the use of drones offers significant advantages in terms of safety, efficiency, and cost-effectiveness.

Flyability’s main competitors in the indoor drone market include DJI, Yuneec, Multinnov, Flybotix, ScoutDI, and Skydio. Flyability’s drones are specifically designed to navigate complex indoor environments, with features such as collision-tolerant technology and obstacle avoidance sensors.

A key difference between Flyability and its competitors is its focus on industrial applications. Flyability’s drones are used for inspections in a variety of industries, including energy, infrastructure, and manufacturing. This focus on specific industries allows Flyability to tailor its products and services to meet the unique needs of its customers.

In summary, Flyability’s pioneering role in the development of indoor drones, its focus on industrial applications, and its unique features such as collision-tolerant technology and obstacle avoidance sensors set it apart from its competitors in the drone market.

Sales and Distribution of Flyability Drones

Flyability drones are sold through both direct and indirect channels. The company has established important key accounts and resellers that play a crucial role in their distribution strategy.

The company’s direct sales efforts are focused on building relationships with key accounts, which include large corporations and government agencies. These key accounts are targeted because they have the resources and budget to purchase larger quantities of Flyability drones.

Flyability also relies on its network of resellers to reach a broader market. These resellers act as intermediaries between Flyability and end customers, allowing the company to expand its reach and tap into new markets.

To achieve their sales goals, Flyability employs various sales strategies, including targeted marketing campaigns and promotions. The company also focuses on providing excellent customer service and support to ensure customer satisfaction and loyalty.

Overall, Flyability’s sales and distribution strategy is designed to maximize the reach and impact of their innovative drone technology. By targeting key accounts, leveraging a network of resellers, and employing effective sales strategies, Flyability aims to become a leader in the drone industry.

Growth and future prospects of Flyability

In terms of its employee count and business growth, Flyability has come a long way since its inception. The company started with a handful of employees in 2014 and has now grown to over 120 employees, with offices and operations in Europe, North America, and Asia. This growth speaks volumes about the company’s innovative products and its ability to meet the demands of the industrial inspection market.

Looking ahead, Flyability has set ambitious goals for itself, aiming to double its revenue every two years. This impressive target is backed by the company’s strong focus on research and development, its commitment to quality, and its ability to deliver customized solutions to clients. With an expanding customer base and a growing need for advanced drone-based inspection solutions, Flyability is well-positioned to achieve its goals.

One of the key factors driving Flyability’s growth is the potential for scalability and expansion in the market. As industries continue to embrace digital transformation, there is a growing demand for efficient and safe inspection solutions. Flyability’s collision-tolerant drones have already made a significant impact in industries such as oil and gas, power generation, and mining. With the potential for further customization and integration with other technologies such as artificial intelligence and automation, Flyability’s drones have immense potential for scalability and growth in the future.

In conclusion, Flyability is a company that has established its reputation as a pioneer in the collision-tolerant drone market. Its growth trajectory and ambitious goals for the future reflect its commitment to innovation, quality, and customer satisfaction. With a strong focus on research and development, scalability, and expanding its customer base, Flyability is poised to achieve continued success in the years to come.

Partnerships and Collaborations of Flyability

Flyability has established several partnerships and collaborations to enhance its capabilities and explore new opportunities. Some of the notable partnerships and collaborations are mentioned below:

Collaboration with GeoSLAM for 3D Modeling: Flyability has partnered with GeoSLAM, a global leader in 3D geospatial technology, to provide 3D modeling solutions for its clients. The collaboration enables Flyability to integrate GeoSLAM’s technology into its drones, allowing them to create accurate, high-resolution 3D models of complex structures.

Participation in the DARPA Sub-T Challenge: Flyability has participated in the DARPA Sub-T Challenge, a competition that aims to develop new technologies for subterranean exploration. Flyability’s drone, the Elios 2, was used to explore and map underground environments, demonstrating its capabilities in challenging environments.

Other Partnerships and Collaborations: Flyability has also established partnerships and collaborations with other organizations, including the Swiss Federal Laboratories for Materials Science and Technology (EMPA), the European Union’s Horizon 2020 program, and various academic institutions. These partnerships enable Flyability to stay at the forefront of technology and innovation in the drone industry.

Conclusion and Outlook

- Safe inspection in confined spaces

- Reduces human entry risks

- High-quality video and images

- Multiple applications and industries

- Easy to use and maneuver

In conclusion, this article has highlighted the innovative technology and solutions offered by Flyability in the field of indoor drones. We have seen how their drones have been applied in various industries, such as inspection and maintenance, search and rescue, and entertainment.

Looking ahead, the future looks promising for Flyability and the indoor drone market. As more industries adopt this technology, the demand for indoor drones is expected to grow. Flyability has the potential to continue to be at the forefront of this market, with their ongoing research and development efforts.

In terms of future developments and innovations, Flyability may look into expanding their product line to include drones with higher payloads, longer flight times, and improved sensors. They may also explore new applications for their drones, such as in the field of agriculture or construction.

Overall, Flyability has shown that they have the expertise and technology to revolutionize the indoor drone market. With their continued efforts and innovation, we can expect to see even more exciting developments from them in the years to come.

Contact Information for Kopterflug Inspection Services GmbH:

Email: [email protected]

Phone: +49 421 40893790

Please direct all inquiries to the above contact information.

Our Inspection Experts

CEO

CEO & Founder

Philipp

CFO & co-owner

Stephan

Operations

Juliana

Maritime Specialist