Tank Inspection with Drone

- Safety: No human entry required.

- Reliability: High-quality visual data.

- Data Quality: Accurate and comprehensive data.

Inspection of tanks for corrosion and damage

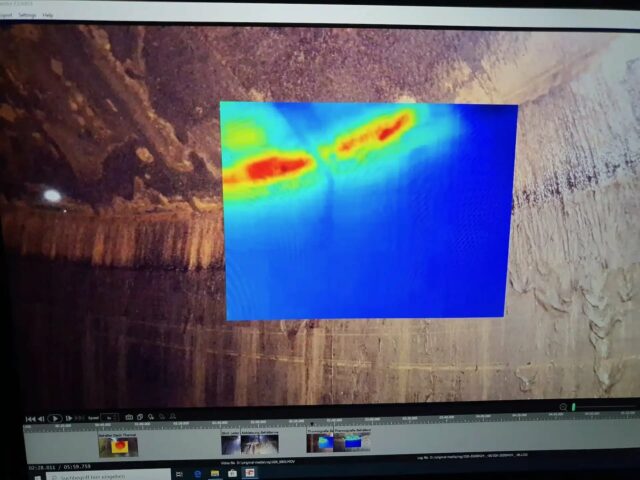

When it comes to inspecting tanks for corrosion and damage, there are a variety of factors to consider. In recent years, we have seen a wide range of damage patterns in tanks and silos, which vary significantly depending on the type of tank, location, and intended use. Tanks and silos also differ fundamentally from each other.

For silos, abrasion is a common issue, while tanks may present a diverse range of damage patterns depending on the material used. Some types of damage may not be entirely detectable or estimable by visual inspection alone. Nonetheless, drones and camera systems are generally suitable for providing an initial assessment of the tank’s condition or determining the need for cleaning before anyone enters the tank. In other cases, the inspection and evaluation of plastic tanks are carried out by the inspectors of testing companies such as TÜV, Dekra, SGS etc, relying on our methods and expertise.

There is a broad spectrum of damage patterns in general. Plastic tanks, for example, may dissolve from the inside out, where acids penetrate the fabric through liner damage. In other cases, tanks may have been improperly calculated, leading to higher hydrostatic pressure in the bottom area (transition between wall and bottom) than planned, or the pedestal on which the tank is placed may not be in order or fit the tank. Plastic tanks are also affected by UV radiation. The temperature of the media filled into the tank within the operational limits of the tank also plays a crucial role. Production errors or improper repairs can also come to light during tank inspections.

Steel tanks are also interesting, with protective coatings or paint depending on the medium. Industrial tanks suffer greatly in the steam and gas zones, particularly in larger tanks like oil storage tanks where inspecting the roof area without building scaffolding can be challenging. Our industrial drone provides significant value here. We have seen numerous types of rust through holes in steel tanks for various reasons. The drone or tank camera provides initial indications before using material thickness measurement techniques.

Contamination is also a crucial factor, both in tanks and silos. For example, grain silos or flour silos in grain mills are often infested with pests that contaminate the product. Since silo inspection is relatively time-consuming, camera inspection can provide immediate insights. Another example of contamination in tanks is sediment buildup on the bottom of firewater tanks over the years, often consisting of substances introduced by water, such as rust from pipes, as well as residues from dissolving tank coatings. Over the years, the amount can become so large that cleaning is recommended to ensure safe firefighting readiness. During the revision time, firewater tanks must resort to mobile firewater tanks or other firefighting concepts.

Safety considerations during tank inspections

Tank inspections are a critical aspect of maintaining safe and reliable industrial operations. However, they also present several safety hazards that must be carefully managed to ensure the safety of workers involved in the inspection process. Here are some safety considerations to keep in mind during tank inspections:

- Confined space entry: Tanks are usually considered confined spaces, which can pose significant safety risks to workers. Employers must ensure that workers entering tanks are properly trained and equipped with appropriate safety equipment, such as gas monitors, breathing apparatus, and harnesses.

- Fall protection: Workers performing tank inspections at elevated heights must be provided with fall protection equipment, such as safety harnesses and lifelines. Employers must also ensure that the equipment is properly maintained and inspected before use.

- Electrical hazards: Many tanks contain electrical equipment, such as pumps and motors, which can present electrical hazards to workers. Employers must ensure that workers are properly trained in electrical safety and that all electrical equipment is properly maintained and inspected.

- Chemical exposure: Tanks can contain hazardous chemicals and substances that can pose health risks to workers. Employers must provide workers with appropriate personal protective equipment, such as gloves, goggles, and respirators, to protect against chemical exposure.

- Equipment safety: Inspecting tanks often requires the use of specialized equipment, such as drones or cameras. Employers must ensure that all equipment used during inspections is properly maintained, inspected, and operated by trained personnel.

By taking these safety considerations into account, employers can help ensure the safety of workers involved in tank inspections and maintain safe and reliable industrial operations.

Inspecting Tanks of different Materials and Purposes - Our Specialty

We have inspected all common types of tanks in dairy plants, breweries, chemical factories, steelworks, waterworks, wastewater treatment plants, food processing plants, pharmaceutical companies, and more. This includes storage tanks, process tanks, pressure tanks, and others, with or without coatings, with or without mixers, cleaned or uncleaned, and even tanks filled with water. Our cameras and endoscopes allow us to easily inspect chemical reactors without putting employees in danger. We can also inspect tanks on ships and even cargo holds.

Examples of the tanks we inspect

- Dairy Plants: Storage tanks, process tanks

- Breweries: Storage tanks, process tanks

- Chemical Factories: Storage tanks, process tanks, pressure tanks, silos, reactors, boilers, storage tanks, tank containers, vacuum tanks

- Steelworks: Storage tanks, process tanks, boilers, storage tanks

- Waterworks: Storage tanks, process tanks, silos, storage tanks

- Wastewater Treatment Plants: Storage tanks, process tanks, storage tanks

Food Processing Plants: Storage tanks, process tanks - Pharmaceutical Companies: Storage tanks, process tanks, reactors, boilers, storage tanks, vacuum tanks

- Offshore: Storage tanks, process tanks, boilers, storage tanks, tank containers

- Underground: Storage tanks, process tanks, boilers, storage tanks

- Transportation: Tank containers

- Cargo Holds: Storage tanks

- Ship tanks: Storage tanks, process tanks

- Aerospace industry tanks: Storage tanks, process tanks, vacuum tanks

- Energy industry tanks: Storage tanks, process tanks, boilers, storage tanks

- Paper industry tanks: Storage tanks, process tanks, boilers

- Construction industry tanks: Silos

- Agriculture tanks: Silos, grain bins

Our Inspection Tools

Tank inspection has come a long way with the advancements in technology. We are proud to offer our clients modern and state-of-the-art inspection tools to ensure the highest level of accuracy and efficiency in tank inspection. Our indoor drones (like the Multinnov Stero 2 or Flyability ELIOS) with extrem bright LEDs and 4K Cameras providing our clients with a detailed view of every inch of their tanks. Our 360° cameras provide a comprehensive view of the tank’s interior, capturing even the smallest details. In addition, our underwater drones can inspect tanks with depths of over 100 meters, and provide high-quality 4K footage of the inspection process. These tools not only increase the reliability and accuracy of inspections but also minimize risks associated with traditional inspection methods. Our team of experienced professionals ensures that these tools are used to their full potential, providing our clients with a detailed report on the condition of their tanks.

Stereo2 Indoor Drone

The use of indoor drones for tank inspection brings several advantages to the table. Firstly, their compact size and design allow for easy access to confined spaces, reducing the need for scaffolding or other access equipment. Secondly, their high-quality 4K cameras enable detailed and accurate inspections, capturing footage that can be used for further analysis. Thirdly, indoor drones equipped with collision avoidance technology can help prevent accidents and damage to the equipment being inspected. Additionally, these drones are capable of positioning themselves in GPS-denied environments, providing reliable inspection data in areas that would otherwise be difficult to access. Lastly, the 14-minute flight time of indoor drones allows for quick and efficient inspections, minimizing downtime for maintenance operations.

360° Cameras for use in Confined Spaces

We develop our own lamps for radial illumination and can capture 360-degree images inside tanks that can be later viewed by inspectors on a computer. 360-degree cameras ensure that no details are missed during inspections.

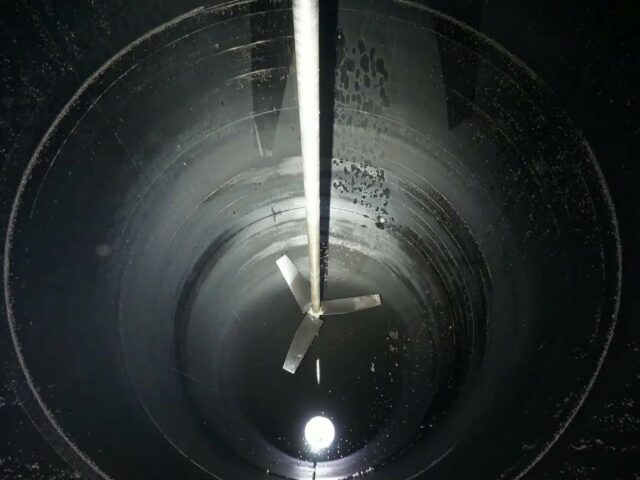

Underwater drone

Underwater drones are ideal for inspecting process vessels, especially for firefighting water tanks and sprinkler tanks. Our small yet powerful underwater drones are essential for these inspections. Weighing only a few kilograms, they come equipped with 4K cameras that can rotate in all directions. With extremely bright lighting and a diving depth of over 100m, even the most complex inspections are possible. As maintenance managers, you can trust us to provide the most advanced and reliable equipment for your tank inspections.

Material-dependent damage to tanks and industrial vessels

- Steel Tanks: Steel tanks are widespread in many industries, such as oil and gas, chemical, and food industries. They are typically suitable for storing liquids such as crude oil, chemicals, and food. They can also be used for storing gases such as nitrogen, carbon dioxide, and compressed air. Steel is the most common material used in the production of industrial tanks. Typical damage patterns are corrosion, rust formation, and fatigue cracks. Corrosion can be caused by the contact of the tank with aqueous or acidic media, which damage the protective film on the surface of the tank. Rust formation can also result from corrosion, but it can also be caused by inadequate coating or welding seams. Fatigue cracks can be caused by the constant loading and unloading of the tank, especially at welding seams. Steel is used in many industries, including chemicals, oil and gas, food, and beverages.

- Stainless steel Tanks: Stainless steel tanks are known for their corrosion resistance and are used in many applications, including the food and beverage industry, the pharmaceutical industry, and the chemical industry. They are suitable for storing liquids such as water, milk, juice, wine, chemicals, and drugs. Stainless steel is a popular material for tanks in the food, pharmaceutical, and cosmetic industries due to its corrosion resistance and hygienic properties. Typical damage patterns in stainless steel are rust stains, stress cracks, and pitting corrosion. Rust stains can be caused by improper cleaning, while stress cracks can be caused by thermal stresses during welding. Pitting corrosion is a type of corrosion that occurs when acidic or chloride-containing media come into contact with the surface of the tank.

- Plastic Tanks: Plastic tanks can be made from various materials, including polyethylene, polypropylene, and PVC. They are often used in the chemical industry and in water and wastewater treatment. Plastic tanks are suitable for storing acids, alkalis, salts, and water.

Plastic tanks are widespread in the chemical industry, electroplating, textile, and food industries. Typical damage patterns are cracks, fractures, and discoloration. Cracks can be caused by mechanical stress or inadequate design, while fractures are due to overloading. Discoloration can result from the action of UV radiation, heat, or chemical reactions with the media stored in the tank.

- Concrete Tanks: Concrete tanks are typically suitable for storing water, wastewater, and chemicals in water and wastewater treatment and the food industry. Concrete tanks are known for their strength and durability and can also be used to store oil and fuels.

Concrete is typically used for large tanks that are used in the water and wastewater industry as well as in the construction industry. Typical damage patterns in concrete tanks are cracks, corrosion of reinforcement, and washouts. Cracks can be caused by shrinkage of concrete or overloading. Corrosion of reinforcement can be caused by the penetration of water or salt-containing media into the concrete. Washouts occur when aqueous media dissolve the cement and other soluble components of the concrete.

- Fiberglass Tanks: Fiberglass tanks are corrosion-resistant and therefore well-suited for storing chemicals and oil. They are commonly used in the chemical and petrochemical industry, power plants, and the food industry.

Fiberglass-reinforced plastic tanks are susceptible to cracks and damage due to mechanical stress or overloading. Weathering, chemical reactions, and aging can also cause damage.

Damage to industrial tanks made from different materials can be caused by a variety of factors. Regular inspection and maintenance are essential to detect and repair damage early, preventing leaks and accidents. Ensure the safety of your industrial tanks by scheduling regular inspections and maintenance. Contact us today to schedule an appointment.

Explanation of the inspection process and methodology

The inspection process and methodology for tank inspections involves a systematic approach to assess the condition of the tank and identify any potential issues that may affect its operation and safety. The process typically includes visual inspections of the exterior and interior surfaces, as well as non-destructive testing (NDT) methods to detect cracks, corrosion, and other defects.

The methodology for tank inspections can vary depending on the type and purpose of the tank, as well as the specific requirements of the inspection. Generally, it involves a detailed examination of the tank structure, components, and operational systems, with a focus on identifying any potential issues that may impact its performance and safety.

The inspection process may also involve the use of specialized equipment and tools, such as drones, 360° cameras, and underwater drones, to access and inspect hard-to-reach areas or areas that may pose safety risks to personnel. Once the inspection is complete, a detailed report is typically prepared that outlines the findings and recommendations for any necessary repairs or maintenance.

Overall, a thorough inspection process and methodology is essential for ensuring the safety and reliability of tanks and other industrial vessels, and can help to prevent costly downtime and damage to equipment.

Our Experience and Collaboration with Testing Institutions

As a provider of inspection services for industrial tanks, we have accumulated years of experience and expertise in the field. One of the key aspects of our work is collaborating with testing institutions, such as the TÜV and Dekra, to ensure that we provide the highest level of service to our clients.

In our experience, the TÜV and other testing organizations have the final say on which inspection methods are acceptable for each tank. This decision is influenced by various factors, such as the tank’s condition and whether it’s safe for a human inspector to enter it.

While it may be tempting to assume that drone or camera footage is just “good enough” for inspections, we know from firsthand experience that this is not the case. We’ve worked closely with the TÜV and other inspection bodies and understand the importance of providing accurate and reliable data to our clients.

The use of drones for tank inspections offers a faster and safer alternative to traditional inspection methods. Drones can reach areas that are otherwise difficult or impossible to inspect, providing valuable information that would otherwise be missed.

At our company, we have a strong working relationship with testing organizations, and we handle all communication related to tank inspections for our clients. Our experience working with these bodies has been overwhelmingly positive, and we’re proud to say that they’re consistently impressed with the quality of our inspection equipment and the enhanced safety it provides for inspectors.

Of course, there may be certain areas of a tank that still require hands-on inspection, such as areas where the surface needs to be checked for damage or corrosion. But for the majority of inspection tasks, drone footage provides a safer, faster, and more thorough option.

In summary, we have a long-standing and successful collaboration with the TÜV and other inspection bodies, and our use of drones for tank inspections has been instrumental in delivering high-quality results to our clients. If you have any questions or would like to learn more about our services, please don’t hesitate to get in touch.

Request a Quote

Frequently Asked Questions

Flyability Elios is a cutting-edge drone technology that enables internal tank inspections to be carried out quickly, safely, and accurately. The drone is equipped with high-resolution cameras and powerful lighting, which allows it to capture detailed images of the interior of tanks.

The inspection process begins by inserting the drone into the tank through a small access point. Once inside, the drone can navigate through tight spaces and around obstacles using its advanced obstacle avoidance technology. The high-resolution cameras allow the operator to view the images in real-time, ensuring that the drone is capturing the necessary data.

One of the major benefits of using Flyability Elios for internal tank inspections is the increased safety it provides. Traditional tank inspections require workers to enter the tank, which can be a dangerous and risky process. With Flyability Elios, workers can remain outside the tank while the drone captures the necessary data. This reduces the risk of accidents and injuries, making tank inspections safer and more efficient.

In addition to safety, Flyability Elios offers a number of other advantages. The drone can inspect tanks more quickly than traditional methods, which saves time and money. It also captures more accurate and detailed data, which allows for more precise analysis of the tank’s condition.

Overall, Flyability Elios is a powerful tool for internal tank inspections. Its advanced technology makes inspections faster, safer, and more accurate, while also reducing costs and improving efficiency. By leveraging this technology, companies can improve their tank maintenance programs and ensure that their tanks are in top condition.

Internal tank inspection by drone has numerous benefits, including:

- Increased safety: By using a drone for internal tank inspection, workers no longer have to enter confined spaces or work at height, thereby reducing the risk of accidents or injuries.

- Improved efficiency: Drone inspections can be completed much faster than traditional inspection methods, as there is no need for scaffolding or complex safety measures. This means that tanks can be returned to service more quickly, reducing downtime and increasing productivity.

- Better data: The use of drones equipped with high-resolution cameras and sensors allows for more detailed data to be collected during the inspection process. This enables more accurate assessments of the condition of the tank and any potential issues.

- Cost savings: By reducing the need for human labor and expensive equipment, drone inspections can result in significant cost savings over traditional inspection methods.

- Non-destructive: The use of drones for tank inspection is a non-destructive method, meaning that the tank remains intact and operational after the inspection. This also means that there is no need for costly and time-consuming repairs or maintenance.

Overall, internal tank inspection by drone offers numerous benefits that make it a highly effective and efficient method for ensuring the safe operation of tanks and other confined spaces.

Preparing for a tank inspection involves several important steps. First, it is crucial to ensure that the tank is emptied and cleaned thoroughly to allow for a proper inspection. Any residue or debris left inside the tank can obscure defects or impede the inspection process.

Next, all necessary permits and authorizations should be obtained to access the site and perform the inspection. This may involve coordinating with the facility’s management, regulatory bodies, and other stakeholders.

It is also important to ensure that all necessary inspection equipment and personnel are available and ready for use. This may include drones or other advanced inspection technologies, as well as trained personnel to operate them.

Finally, a detailed inspection plan should be developed and communicated to all relevant parties to ensure that the inspection is conducted efficiently and safely. This may involve identifying any potential hazards or risks associated with the tank, and taking appropriate precautions to mitigate them.

Our Inspection Experts

CEO

CEO & Founder

Philipp

CFO & co-owner

Stephan

Operations

Juliana

Maritime Specialist