Inspection of tanks and silos by drone

- Safe access without scaffolding and foot traffic

- Comprehensive 360° inspection

- Fast results and analyses

Safe inspection of tanks and silos by drone in industrial plants

Traditional inspections of tanks and silos are often time-consuming and cost-intensiveas they often require the use of scaffolding and working platforms. With our drone technology, we can carry out inspections quickly and safely without the need for complex scaffolding work. We work with TÜV inspectors, surveyors and other inspection organisations to ensure the highest quality and safety standards.

-

Maximum security

Tank and silo inspections without scaffolding or working platforms. -

Comprehensive inspection

Complete documentation and precise localisation of damage in tanks and silos. -

Time and cost efficient

No need for time-consuming and cost-intensive scaffolding and working platforms. -

Meaningful reports

High-resolution photos and precise localisation of findings in tanks and silos.

A selection of our customers and partners

Corrosion and specific defects in steel tanks and plastic tanks

With the Corrosion of steel tanks and the special challenges of plastic tanks There are considerable differences between the two materials, as they react differently to environmental influences and storage conditions. While steel tanks are mainly affected by electrochemical corrosion, plastic tanks have other specific problems that need to be taken into account.

Corrosion and problems with steel tanks

Steel tanks are particularly susceptible to corrosion due to their material properties and frequent contact with water and chemicals. The main problems and protective measures are

- Electrochemical corrosion:

As mentioned above, electrochemical corrosion is the biggest problem with steel tanks, especially when they come into contact with water, moisture or aggressive chemicals. Rust formation is a common problem that can jeopardise structural integrity. - Microbially induced corrosion (MIC):

Steel tanks are susceptible to microbially induced corrosion, especially in the oil and gas industry or in tanks that store organic materials or water. Sulphate-reducing bacteria (SRB) are particularly harmful as they produce aggressive substances such as hydrogen sulphide, which promotes corrosion. - Coatings and cathodic protection:

The use of protective coatings (e.g. epoxy resin or polyurethane) and cathodic protection (sacrificial anodes) are important measures to extend the service life of steel tanks and prevent corrosion. Regular maintenanceWithout regular inspections and maintenance, corrosion can progress unnoticed and cause considerable damage.

Special problems with plastic tanks

Plastic tanks (usually made of polyethylene, polypropylene or glass fibre reinforced plastic) are not susceptible to corrosion in the conventional sense, as they are not made of metal. However, plastic tanks have other specific challenges:

Chemical decomposition:

Plastic tanks are more favourable than certain chemicals which can attack the structure of the material. Some aggressive chemicals or solvents can weaken the plastic or make it brittle, leading to cracks or leaks.

Stress crackingSome chemicals, especially organic solvents, can cause stress cracking in the plastic. These cracks can spread over time and eventually lead to leaks.UV degradation:

Plastic tanks that are located outdoors are the UV radiation exposed to the sun. Long-term exposure to UV rays can degrade the material and make it brittle. This process is known as UV degradation and can significantly reduce the durability of the tanks.

Solutions: In order to avoid this problem, plastic tanks are often UV stabilisers treated or by Colour coatings or Covers protected.Temperature resistance:

Plastic tanks are more sensitive to extreme temperatures than steel tanks. At high temperatures, the plastic can deform or soften, jeopardising the structural integrity. At very low temperatures, plastic can become brittle and susceptible to cracking.Mechanical damage:

While steel tanks can withstand mechanical stress relatively well, plastic tanks are more susceptible to Mechanical damage. Scratches or knocks can lead to cracks or leaks, especially in tanks that are subject to heavy loads or are installed outdoors.Diffusion:

Another problem with plastic tanks is the Permeability. Some chemicals can diffuse through the plastic, which can lead to a gradual loss of the contents or contamination of the environment. This is particularly important when storing flammable liquids or Solvents relevant.Long-term exposure:

Plastic tanks are also subject to the so-called Creep deformation. This means that the material can gradually change its shape under continuous load (e.g. due to the weight of the contents). This can lead to a structural weakening of the tank, especially in the case of large or highly filled tanks.

Comparison between steel and plastic tanks

| Aspect | Steel tanks | Plastic tanks |

|---|---|---|

| Susceptibility to corrosion | High risk of corrosion, especially with water and chemicals | No corrosion in the conventional sense, but chemical attacks possible |

| Protective measures | Protective coatings, cathodic protection, regular inspections | UV stabilisers, chemical resistance, mechanical protection measures |

| Chemical resistance | Depending on the coating, can be attacked by aggressive chemicals | Good resistance to many chemicals, but certain substances can cause stress cracks |

| Mechanical stability | Very high, resistant to mechanical loads | Sensitive to scratches, impacts and mechanical damage |

| Maintenance | Regular inspection and maintenance required to prevent corrosion | Less maintenance required, but regular checks for UV damage and cracks |

Both Steel as well as Plastic tanks have specific challenges that must be taken into account when using them. While steel tanks are susceptible to Electrochemical corrosion and Microbially induced corrosion plastic tanks have problems such as chemical degradation, UV degradation and mechanical weaknesses. Both tank types require specific protective measures to extend their service life and ensure their functionality.

Save time and money on tank inspections - talk to our experts now

Drone inspections for tanks and silos - time-saving, precise and safe

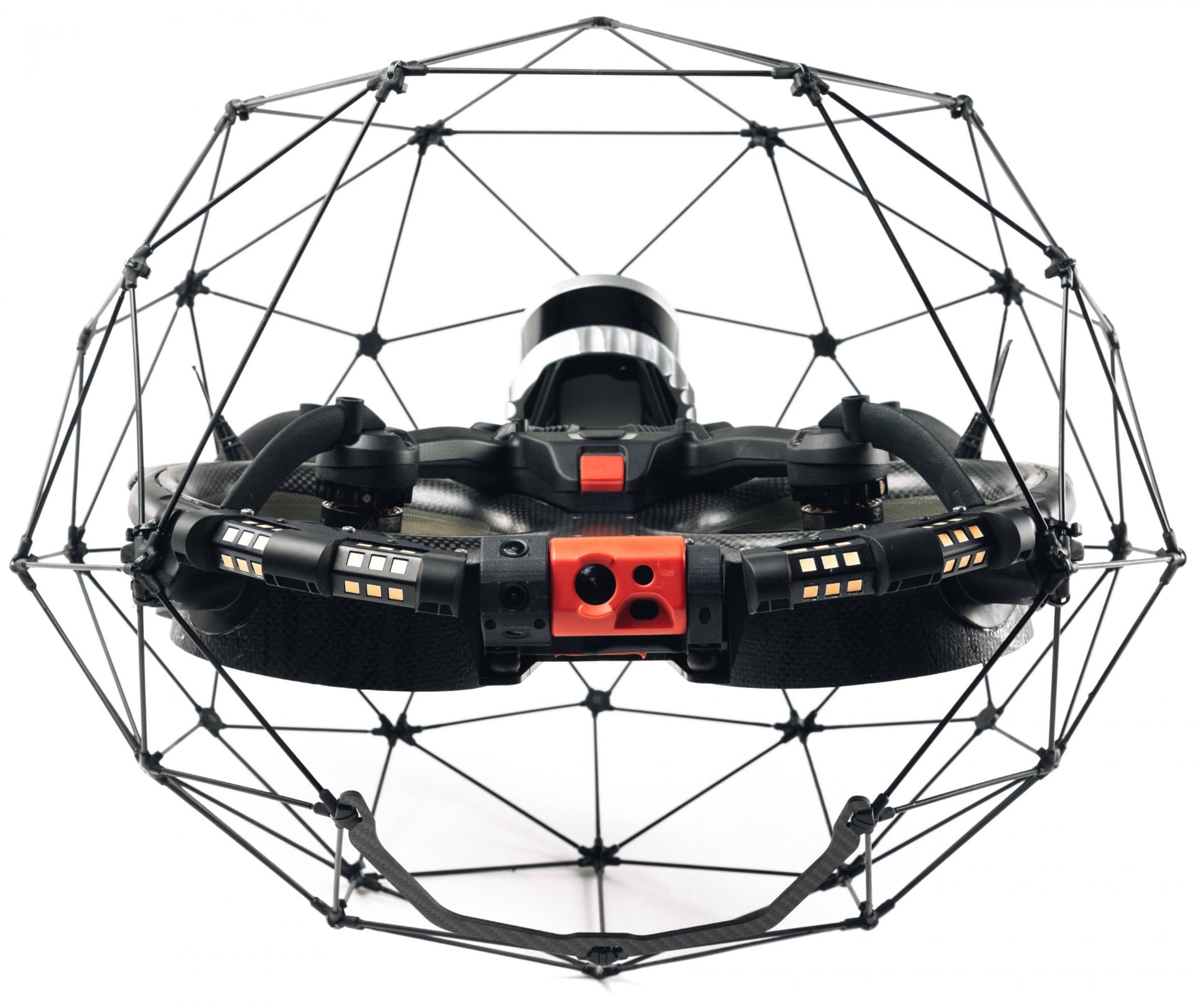

- With the Drone inspections of the Flyability ELIOS 3 we offer a modern solution for inspecting tanks and silos in industrial plants. Our drones capture high-resolution images and precise data to perform a detailed inspection of hard-to-reach internal areas. We work closely with inspection organisations to ensure that all inspections meet the highest quality and safety standards.

- Thanks to our years of experience in the inspection of tanks we can precisely inspect and document specific defects such as corrosion on steel tanks, damage to coatings and damage to GRP tanks. Our drones make it possible to precisely detect even the smallest defects and quickly initiate maintenance measures.

- We can also inspect silos safely and efficiently. Drone inspection makes it possible to recognise specific defects such as abrasions and other structural damage at an early stage and documented to ensure long-term stability and security.

- Rely on Drone inspections with the Flyability ELIOS 3 and benefit from our extensive experience, modern technology and cooperation with leading inspection associations to optimise the safety and efficiency of your tank and silo inspections.

Save time and money on tank inspections - talk to our experts now

-

Inspection with minimum downtime

Extremely efficient inspection with the Flyability ELIOS drone. -

Maximum occupational safety

Tanks and silos are inspected remotely and reports are conveniently generated on screen. -

Precise localisation of the findings

The ELIOS 3 drone generates a point cloud from which the precise flight path and the location of the damage can be read.

Experts for industrial inspections

What are the advantages of inspecting tanks and silos with the Flyability ELIOS 3 drone?

The Inspection of industrial tanks such as steel tanks and GRP tanks with the Flyability ELIOS 3 drone enables a safe Checking areas that are difficult to access ohne Gefährdung von Mitarbeitern. Sie erkennt präzise Defekte wie Korrosion, Mikrorisse, Wanddickenschwächung, Osmose, Delamination und UV-Schäden. Mit hochauflösenden Kameras und präzisen Sensoren liefert die Drohne genaue Daten für eine zuverlässige Zustandsbewertung. Unsere Inspektionen sind schnell und effizient, minimieren Stillstandzeiten und vermeiden teure Ausfälle. Durch die enge Zusammenarbeit mit Prüfverbänden gewährleisten wir, dass alle Inspektionen höchsten Standards entsprechen und Defekte frühzeitig erkannt werden.

How does drone inspection differ from conventional inspection methods for tanks and silos?

In contrast to traditional inspections, which require scaffolding, working platforms or rope access and expose employees to hazards, the Drone inspection a fast and safe solution without interrupting operations. The Flyability ELIOS 3 drone, equipped with high-resolution cameras and advanced sensors, enables precise inspection of hard-to-reach areas and detects defects such as corrosion, cracks and deformations at an early stage. Laser scanning and 3D mapping can also be used to create accurate models for maintenance planning. This method saves time and money and protects personnel from unnecessary risks.

Which tanks and silos can be inspected with the Flyability ELIOS 3 drone?

The Flyability ELIOS 3 drone can be used to efficiently inspect various types of tanks and silos in industry and power plants. These include

- Storage tanks: Cylindrical tanks, spherical tanks and rectangular tanks made of carbon steel, stainless steel, aluminium, GRP and concrete. These tanks are used to store raw materials, water, chemicals and fuels.

- Pressurised container: Spherical tanks and cylindrical pressure tanks made of stainless steel, alloy steel and carbon steel, which are used to store gases and liquids under high pressure.

- Silos for bulk goods: Cylindrical silos, bunker silos and conical silos made of concrete, steel, stainless steel and GRP, which are used to store solid materials such as grain, cement, coal and chemicals.

- Spherical tanks: Spherical tanks made of carbon steel, stainless steel and alloy steel, specially designed for the storage of liquefied gases (LNG, LPG) under pressure and at low temperatures.

- cooling tanks: Insulated stainless steel tanks used in the food and chemical industries for storage at low temperatures.

- Acid tanks and chemical storage tanks: Tanks made of polyethylene, polypropylene, GRP and stainless steel for the storage of corrosive chemicals such as acids, alkalis and solvents.

- Sedimentation tanks: Tanks made of steel and concrete with a funnel-shaped bottom, used in sewage treatment plants and for wastewater treatment.

- Storage tanks for liquid fuels: Tanks made of carbon steel, stainless steel and GRP, specially designed for the storage of fuels such as diesel, petrol and heavy fuel oil.

- Biogas and fermentation tanks: Gas-tight tanks made of steel, stainless steel, GRP and concrete, which are used for the fermentation of organic waste in biogas plants.

- Sprinkler tanks: Vertically installed tanks made of steel, GRP and concrete that store water for firefighting. Also Underwater inspections are possible.

- Extinguishing agent storage tanks: Pressure-tight containers made of stainless steel, alloy steel and GRP for storing special extinguishing agents.

- Cooling towers and water reservoirs: Open or closed tanks made of steel, concrete and GRP for water cooling in power stations.

Thanks to the Flyability ELIOS 3 drone, all these tanks and silos can be safely and efficiently inspected to detect defects such as corrosion, cracks, coating delamination, osmosis, delamination and other structural damage at an early stage.

How safe is it to inspect tanks and silos with the Flyability ELIOS 3 drone?

The Flyability ELIOS 3 drone enables safe inspections of confined, hard-to-reach and potentially hazardous areas without employees having to take risks. It is controlled from the ground or outside the structures and delivers high-resolution images and precise data. Its robust design and ability to navigate safely in low light and confined environments minimises the risk of accidents. This method is ideal for inspecting tanks and silos that are pressurised, chemically contaminated or difficult to access, providing an efficient and thorough solution without putting personnel at risk.

How long does it take to inspect tanks and silos with the Flyability ELIOS 3 drone?

The duration of an inspection of tanks and silos with the Flyability ELIOS 3 drone depends on the size, condition and complexity of the structures to be inspected. In general, a drone inspection is significantly faster than conventional methods as no scaffolding, working platforms or rope access techniques are required. Smaller tanks or simple silo structures can often be fully inspected within a few hours. For larger tanks, complex systems or when several tanks and silos are inspected at once, the inspection can take a whole day or longer. However, with efficient data collection and documentation, inspection times can be significantly reduced compared to traditional methods, minimising downtime and optimising operations.

How are the targets for the drone inspection of tanks and silos defined and controlled?

The objectives for the drone inspection of tanks and silos are defined in advance in close consultation with the customer. The first step is to clarify why the inspection is being carried out - whether it is for a routine check, to document damage or to comply with legal requirements. We also discuss whether testing organisations or external experts are involved and what specific requirements they have for the inspection. Based on this information, we plan the inspection specifically according to the customer's needs. During the inspection, we ensure that all relevant areas are thoroughly checked and that the data collected corresponds to the defined objectives. In this way, we ensure a customised inspection solution that meets the highest standards and delivers precise results.

Is the ELIOS 3 easy to operate and do I need special training?

What happens if defects or damage are discovered during the inspection of tanks and silos?

Can the drone inspection of tanks and silos also be carried out during ongoing operations?

How can I book a drone inspection for my tanks and silos?

Are ultrasonic inspections (UT measurements by drone) also possible during the tank inspection?

Yes, ultrasonic testing (UT measurements) can be carried out. UT measurements are an effective method of checking the material thickness of tank walls and detecting potential corrosion or erosion damage. These measurements provide a precise assessment of the condition of the tank and help to plan necessary maintenance measures at an early stage. By using modern drones and special UT sensors, the measurements can even be carried out in hard-to-reach places, which shortens inspection times and increases safety.

-

Inspection with minimum downtime

Extremely efficient inspection with the Flyability ELIOS drone. -

Maximum occupational safety

Data is recorded from outside the tanks and silos, and reports are conveniently generated on the screen. -

Precise localisation of the findings

The ELIOS 3 drone generates a point cloud from which the precise flight path and the location of the damage can be read.

Request tank inspection

- We look forward to your enquiry and will respond promptly!