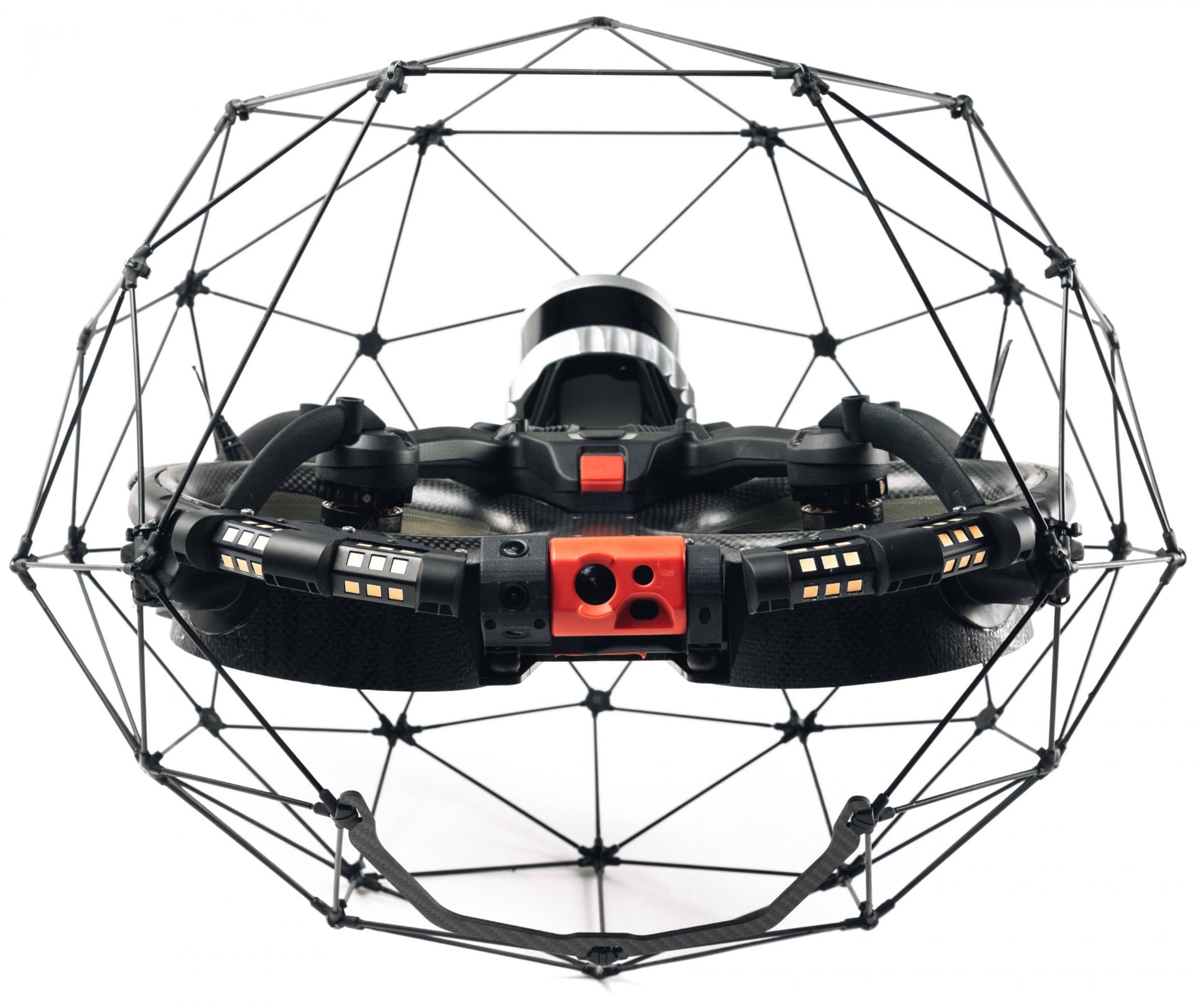

Inspection with the Flyability ELIOS 3 drone

With the Flyability ELIOS 3 drone We are setting new standards in the inspection and digitalisation of Industrial plants and power stations .

- Access to Confined Spaces that are difficult to access

- Precise LiDAR measurement and 3D scans

- Inspection without scaffolding, cranes and working platforms

Flyability ELIOS 3 - simple, safe and complete inspection for industry and power plants

Based on the requirements for an inspection that must provide comprehensive, meaningful and precisely localisable data and the ability to repeat inspections exactly, there is only one drone that meets these requirements in my opinion: the Flyability ELIOS 3.

-

Maximum security

The Flyability Elios 3 drone replaces risky on-site inspections and thus protects your employees. -

Comprehensive inspection

Lidar technology enables precise measurements and detailed recordings even in the most demanding environments. -

Time and cost efficient

No need for scaffolding, climbing operations, cranes and reduced downtimes. -

Meaningful reports

High-resolution photos, thermographic and lidar data complete our analyses.

A selection of our customers and partners

Flyability ELIOS 3: Drone inspections for greater safety and less downtime in industry

For maintenance engineers in industry, efficiency, safety and accuracy are the top priorities when it comes to inspecting and maintaining systems. Here we offer Drone inspections - especially with the Flyability ELIOS 3 - has considerable advantages over conventional methods.

- The Flyability ELIOS 3 is specially designed for inspections in industrial environments. It makes it possible to inspect areas that are difficult or dangerous to access, so-called Confined Spaceswithout the use of scaffolding, cranes or working platforms. This means no time-consuming and costly dismantling of plant components or downtime that could disrupt the production process. With the ELIOS 3, inspections can be carried out while the systems are in operation, which significantly shortens maintenance cycles and ensures operational continuity.

- Another significant advantage is the Precise data acquisition using LiDAR technology and high-resolution cameras. The ELIOS 3 enables exact 3D measurement and high-precision scans that allow detailed analyses and reporting. This precise data is not only essential for documenting damage and defects, but also forms the basis for efficient digital asset management. They help maintenance engineers to plan targeted maintenance measures, recognise risks at an early stage and deploy resources efficiently.

- In addition, the ELIOS 3 safety for the maintenance team. Instead of sending employees into potentially dangerous areas, the drone takes over the inspection - safely and efficiently, without putting staff in danger. This prevents accidents and improves working conditions.

- To summarise, the Drone inspection with the Flyability ELIOS 3 is a modern solution for industrial maintenance staff that saves time, reduces costs and maximises safety. It is the ideal tool for optimising maintenance processes and ensuring the availability and reliability of systems.

Save time and money on inspections - talk to our experts now!

-

360° collision protection

The Flyability ELIOS 3 enables safe inspections in confined, hazardous spaces without risk to employees. -

4K camera and thermal camera:

Delivers razor-sharp images and videos even under the most difficult conditions, for precise analyses. -

Lidar scanner:

Creates detailed 3D point clouds in real time to inspect complex structures safely and efficiently.

Experts for industrial inspections

What are the main advantages of the Flyability ELIOS 3 compared to other drones?

The Flyability ELIOS 3 is specially designed for inspections in confined, difficult to access and dangerous areas (confined spaces). It offers unique advantages such as collision-resistant design, LiDAR-based 3D scanning, high-resolution imaging, and increased safety by eliminating the need for scaffolding or climbers. This reduces costs and increases efficiency and safety.

Which areas of application are ideal for the Flyability ELIOS 3?

What technologies does the ELIOS 3 use for inspections?

How safe is the ELIOS 3 for use in hazardous environments?

What kind of data can the ELIOS 3 record?

How long can the ELIOS 3 stay in the air?

Is the ELIOS 3 easy to operate and do I need special training?

Can the ELIOS 3 be used in dark or dusty environments?

What software is used for data analysis and reporting?

How robust is the ELIOS 3, and can it withstand impacts or collisions?

Can the Flyability Elios 3 also be used for ultrasonic testing (UT measurements)?

Yes, the Flyability Elios 3 can be used for ultrasonic testing (UT measurements) can be used. By integrating special UT sensors, it is possible to measure material thicknesses and Corrosiondetect erosion or other defects in hard-to-reach places. This function is particularly suitable for inspections in areas such as petrochemicals, the oil and gas industry and power generation, where structures such as tanks and pipes need to be inspected regularly. The advantage of using the Elios 3 for UT measurements is that there is no need to use scaffolding or climbers, which significantly reduces inspection time and costs.

-

3D measurement & geometry acquisition

We offer accurate measurements and precise documentation of your systems by precisely recording complex structures and providing this data for your DAM system. -

Quick identification of problem areas:

The precise localisation of critical points means that potential risks can be quickly identified and addressed, and the findings can also be assigned to TÜV or testing associations at any time. -

Unlimited possibilities:

Our point cloud data can be exported in various formats to ensure smooth further processing in your existing systems. Whether CAD, BIM or special inspection and maintenance software - we provide you with the data in the required format.

Flyability ELIOS Request inspection

- We look forward to your enquiry and will respond promptly!