Insight - Your access to technology and innovation

In our Insight section, you will find compact and easy-to-understand articles on the latest technologies, innovative processes and practical solutions. Whether technical insights, inspections or industry-specific trends - here you will find everything you need to know in a nutshell.

19 January 2025

Safe and efficient with the latest drone and ROV technology: the dismantling of nuclear power plants is being revolutionised. Discover how precise inspections and advanced methods are overcoming the challenges of dismantling. ...

13 January 2025

The truth about the job of a drone pilot: not an apprenticeship, but an additional qualification with limited prospects. Our article explains why it takes more than just flying skills and how you can use drones sensibly in your job. ...

11 January 2025

Drones have become an indispensable tool in the process industry for safely and efficiently inspecting areas that are difficult to access. This article shows 10 real-world use cases of how drones are revolutionising inspections in tanks, chimneys, pipelines and more. With state-of-the-art technology such as 4K cameras, LiDAR and thermography, drones provide accurate data, reduce downtime and increase safety. Find out how companies can not only reduce costs by using drones, but also take the maintenance of their systems to a new level.

5 November 2024

Concrete is indispensable in industrial plants - from supporting structures and foundations to chimneys and silos. But like all materials, concrete is susceptible to damage that can affect its load-bearing capacity and service life. This article looks at the seven most common types of concrete damage in industrial environments: from mechanical cracking and spalling to chemical influences such as carbonation and chloride attack and biological damage caused by algae growth. Find out how modern inspection methods help to detect these damages at an early stage and how preventive measures can reduce maintenance costs and increase safety.

4 November 2024

Modern hybrid inspections are revolutionising industrial plant inspection. By combining drone technology and targeted traditional inspection, companies can reduce their inspection costs by up to 80% while increasing efficiency. Without costly scaffolding and expensive plant shutdowns, drones provide a fast and accurate initial assessment, followed by a pinpoint detailed inspection only where necessary. Find out how this innovative approach not only saves you time and money, but also provides comprehensive digital documentation for a sustainable maintenance strategy.

3 November 2024

Drones such as the DJI M30T and the collision-tolerant Flyability Elios 3 are revolutionising industrial inspection: they make plant maintenance safer, more efficient and more cost-effective. With advanced multi-sensor technology, AI and digital twin technology, they effortlessly master even hard-to-reach and high-risk areas. Find out why these technologies are taking industrial inspection to the next level - and will soon be indispensable.

16 October 2024

Working in confined spaces is extremely risky. In this article, we highlight 20 hazards that occur in confined spaces and show how drones such as the Flyability Elios 3 help to minimise risks.

16 October 2024

Underwater inspections are an important part of many sectors, from shipping to energy supply. Thanks to modern technologies such as underwater drones (ROVs), these inspections can now be carried out more efficiently and safely. Here are 10 key facts that illustrate the importance and possibilities of underwater inspections:

15 October 2024

Industrial maintenance is on the verge of a revolution - and drones are the key to this. They are replacing costly and risky traditional inspection methods, reducing downtime and providing accurate data in real time. With technologies such as LiDAR and the creation of digital twins, drones are revolutionising the way industrial plants are maintained and monitored. Discover how drone inspections increase efficiency, reduce costs and ensure worker safety at the same time.

14 October 2024

Non-destructive testing (NDT) encompasses a variety of techniques that make it possible to assess the integrity and safety of materials and components without damaging them. This article details the eight main NDT methods, including visual testing (VT), ultrasonic testing (UT), X-ray and gamma ray testing (RT) and magnetic particle testing (MT). Each method offers specific advantages and areas of application, from aerospace inspection to industrial pressure vessel monitoring. Modern technologies such as the Flyability Elios 3 drone are revolutionising visual inspection in particular by making inspections in hard-to-reach places safer and more efficient.

14 October 2024

Material fatigue is an insidious problem that can significantly weaken machines and structures in industry. Cyclical loads often lead to microcracks that go unnoticed and can result in expensive breakdowns and repairs without regular inspections. Non-destructive testing, such as visual inspections, ultrasonic measurements and the use of modern drones, play a crucial role in detecting material fatigue at an early stage. In this article, you will learn the most important facts about material fatigue and how preventive inspections help to extend the service life of your systems and avoid costly damage.

13 October 2024

Sprinkler tanks are at the heart of every fire protection system - but what happens when these vital systems fail? From the water exchange zone to the foil lining, various defects can impair functionality. The good news is that modern inspection technology is revolutionising the maintenance of these safety-critical systems. In this article, we will show you the typical damage that can occur in underground and steel tanks and how innovative underwater drones enable efficient inspection - without the need for time-consuming tank draining. Find out how you can not only save costs through preventive inspections, but also optimise the safety of your fire protection system.

13 October 2024

Pipe bridges are the lifelines of modern industrial plants - they transport media, energy and resources to exactly where they are needed. However, this indispensable infrastructure is under constant strain: wind and weather, thermal stress and mechanical impact all take their toll.

Regularly inspecting these often widely ramified and difficult to access structures used to present companies with major challenges. Traditional inspection methods required complex scaffolding, expensive cherry pickers or risky rope access techniques. But Industry 4.0 brings a revolutionary solution: state-of-the-art inspection drones are changing the way we monitor and maintain pipe bridges.

These high-tech flying systems enable detailed inspections from the air - precisely, safely and cost-effectively. Equipped with high-resolution cameras and state-of-the-art sensor technology, they detect even the smallest damage before it can grow into serious problems. Find out in this article how drone inspections are transforming the maintenance of pipe bridges and what benefits this innovative technology offers for your plant.

13 October 2024

Micro-ROVs offer a safe and efficient alternative to traditional diver operations and system pumping. They navigate in confined spaces, stir up less sediment and are easy to sanitise, especially in drinking water applications. Without complex pre-planning and safety concepts, micro-ROVs can quickly deliver high-resolution data - ideal for modern inspection requirements. In this article, you will learn the 7 key advantages why Micro-ROVs are increasingly replacing conventional methods.

13 October 2024

The industry is at a turning point: innovative drone technology is revolutionising the preventive maintenance of industrial plants. In this article, we show you 5 compelling reasons why predictive maintenance with drones not only reduces costs, but also significantly increases the safety and efficiency of your equipment. Find out how modern drone inspections prevent costly breakdowns and maximise the service life of your industrial equipment.

12 October 2024

The Elios 3 takes industrial indoor inspection to a new level. As the world's first indoor drone with LiDAR technology and IP44 protection, it sets new standards for precise inspections in demanding industrial environments. Discover the ten key innovations that make the Elios 3 the most advanced inspection drone in its class.

12 October 2024

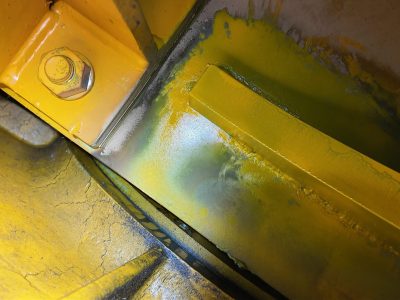

Corrosion causes billions in damage in industry every year. From pitting to crevice corrosion - the different types of corrosion require different prevention strategies. Discover the 8 most important types of corrosion and find out how innovative drone inspections can detect damage at an early stage and prevent costly system failures.

11 October 2024

Steel tanks are the backbone of industrial storage - but ageing and corrosion jeopardise their integrity. Modern drone inspections are revolutionising tank monitoring through precise damage detection and safe inspections. Discover the seven key benefits that drone technology offers for professional tank inspection.