AI assisted inspection

- Increased Efficiency: AI-assisted inspection automates repetitive tasks, enabling faster and consistent analysis of data and images.

- Enhanced Accuracy: AI algorithms can identify defects and anomalies with higher precision than human inspectors, reducing the risk of overlooking critical issues.

- Data-Driven Insights: AI systems can generate actionable insights from inspection data, helping businesses optimize processes and make informed decisions.

Improve efficiency and accuracy with AI-assisted digital inspections

In the ever-evolving industrial landscape, technological advancements have continually redefined operational standards, pushing the boundaries of efficiency and safety. One such technology, artificial intelligence (AI), has ushered in a new era of precision and reliability for inspection services. Companies like Kopterflug are at the forefront of this transformation, leveraging AI-powered drones, ROVs (Remotely Operated Vehicles), cameras, and crawlers to redefine the very essence of industrial inspection.

- Accuracy Like Never Before

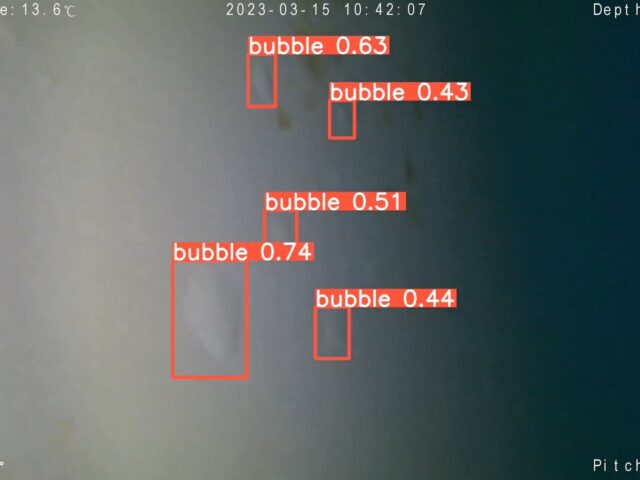

With AI integration, inspection tools can not only capture images but analyze them in real-time. Traditional inspections often rely on the human eye, which, despite its prowess, can overlook small anomalies or imperfections. AI-powered inspections ensure that even the minutest of discrepancies are flagged, significantly improving the accuracy of the inspections. - Enhanced Safety Measures

Dangerous, hard-to-reach, or hazardous environments pose significant risks to human inspectors. Drones and ROVs, can safely capture Data, ensuring inspections are done comprehensively without compromising on safety. Whether it’s the high reaches of a transmission tower or the submerged depths of an offshore oil rig, Kopterflug’s equipment can get there, ensuring humans are kept out of harm’s way. - Time and Cost Efficiency

Time is an invaluable resource in the industrial realm. AI-fueled inspections, facilitated by drones and crawlers, drastically reduce the time spent on manual and often tedious checks. By automating data collection and initial analysis, companies can save significant manpower hours, translating to tangible cost savings. - Predictive Maintenance

One of the game-changing advantages of integrating AI into inspection services is its potential for predictive maintenance. Instead of merely identifying existing issues, AI can forecast potential problem areas based on patterns, wear and tear analysis, and other predictive data. This preemptive approach can save industries millions by preventing catastrophic failures and optimizing repair schedules. - Seamless Data Integration

Kopterflug’s AI-driven tools don’t just stop at capturing and analyzing; they seamlessly integrate with other enterprise systems, providing a holistic view of the asset’s health and performance. This integrated data approach ensures all stakeholders, from maintenance crews to top-tier management, have access to real-time, actionable insights. - Environmental Impact and Sustainability

AI-assisted inspection with drones, rovs and cameras can significantly reduce the environmental footprint of inspections. By minimizing the need for large crews, heavy machinery, and extensive on-site durations, ecosystems are less disturbed, and the carbon footprint of operations is considerably reduced.

The AI advantage in industrial inspection isn’t merely a futuristic promise; it’s a present-day reality reshaping how industries view and conduct their inspection protocols. Kopterflug, with its state-of-the-art AI-powered drones, ROVs, cameras, and crawlers, stands as a testament to the transformative power of technology, leading the way for a safer, more efficient, and data-driven future.

AI-Powered Inspection: Spotting Flaws Like Never Before

In the realm of industrial operations, where precision, safety, and efficiency are paramount, the ability to detect defects swiftly and accurately holds immense significance. The visual and thermal inspection capabilities of Artificial Intelligence (AI) have emerged as transformative tools in this pursuit. With the capability to analyze images, video footage, and thermal data, AI-powered defect detection is redefining maintenance practices across various industries.

As technology evolves, so does the potential to identify anomalies and irregularities that might otherwise remain unnoticed to the human eye. Whether it’s pinpointing signs of corrosion, discerning cracks and fractures, or identifying temperature anomalies, AI’s prowess in visual and thermal defect detection is shaping a new era of maintenance efficiency and reliability. This article delves into the tangible benefits of AI-driven defect detection in enhancing asset management, bolstering safety, and ensuring the longevity of vital infrastructure. Join us on a journey through the transformative landscape of visual and thermal defect detection, and discover how AI is revolutionizing the way we safeguard and optimize industrial assets.

Defects Detected by AI in Visual and Thermal Inspection:

- Corrosion and Rust: AI can spot signs of corrosion and rust on metal surfaces, such as pipelines or industrial machinery, from images or videos.

- Cracks and Fractures: AI can identify cracks and fractures in structures like bridges and buildings by analyzing visual imagery.

- Wear and Tear: AI can detect wear and tear on components and equipment, assessing their condition from visual cues.

- Temperature Anomalies: AI can analyze thermal images to identify unusual temperature variations in machinery or electrical systems, indicating potential issues.

- Fluid Leaks: AI can identify fluid leaks in pipelines or equipment by analyzing images for changes in color, shape, or patterns.

- Electrical Hotspots: AI can detect hotspots in electrical systems or components from thermal images, highlighting potential electrical issues.

- Misalignments: AI can identify misalignments or irregular positioning of components from images, ensuring proper functionality.

- Structural Integrity: AI can assess the structural integrity of buildings, bridges, and infrastructure by analyzing visual cues like cracks or deformations.

- Equipment Defects: AI can spot defects in manufactured parts or equipment from visual imagery, ensuring quality control.

- Insulation Problems: AI can identify insulation problems in electrical systems or thermal insulation materials from images or thermal data.

- Material Degradation: AI can detect material degradation or inconsistencies in assets like pipelines, tanks, or machinery using visual analysis.

- Concrete Damage: AI can identify concrete damage, such as cracks or spalling, in structures from visual imagery.

- Fluid Flow Irregularities: AI can analyze images or videos to detect irregularities in fluid flow patterns, revealing blockages or malfunctions.

- Environmental Monitoring: AI can assess environmental conditions from imagery, such as monitoring changes in vegetation or water levels around structures.

Take Your Maintenance to the Next Level: Discuss AI-Powered Defect Detection with Our Experts.

Mastering AI-Driven Inspections: A Comprehensive Guide

If you’re curious about how technology is revolutionizing industrial inspection, you’re in the right place. At Kopterflug, we’ve devised a method where AI-driven drones and ROVs are employed for identifying and analyzing defects. Here’s how we approach it and how you can get started too:

- Choosing the Right Equipment

Our first step involves selecting the appropriate equipment for the job at hand. We employ cutting-edge drones and ROVs designed specifically for industrial applications.

- Data Collection

After picking out the equipment, we go into an extensive data collection phase. Our drones and ROVs capture thousands of images and videos of the structure to be inspected. This data serves as the foundation for training our AI model.

- Data Cleaning and Preparation

Once the data is gathered, preprocessing is done. This means we remove any unusable or irrelevant data, ensuring only high-quality data is utilized for training the AI model.

- Training the AI Model

Here’s where the magic happens: With the collated data, we train our AI model. This process involves “teaching” the AI to identify defects or anomalies in the captured images. With every set of data we add, the AI becomes more precise and efficient.

- Implementation and Real-time Analysis

After the AI model is sufficiently trained, it’s deployed in real inspection projects. When conducting inspections, our model can now spot anomalies in real-time and report them to the inspectors on-site.

- Reporting and Feedback

Post-inspection, we create a detailed report that lists all the defects identified by the AI. Not only does this report assist our clients in addressing current issues, but it also provides valuable insights into potential areas of concern in the future.

- Continuous Improvement

At Kopterflug, we’re constantly striving to enhance our AI models. With every project, we learn and leverage this knowledge to refine our model for future inspections.

Conclusion: Incorporating AI into the inspection process isn’t just a tech upgrade; it’s a necessity in our fast-paced, data-driven world. At Kopterflug, we assist businesses in making the transition with ease, ensuring their inspections are more accurate, efficient, and future-proof.

Unlocking the Power of AI: What You Need to Know

Imagine AI as a helpful assistant that makes industrial inspection much better. It uses smart computer programs to look at things like machines, buildings, and products. AI is super good at spotting tiny problems that might be hard for humans to see. It looks at pictures, videos, and even thermal data to find things like cracks, rust, or defects.

AI also works really fast, much faster than humans. It quickly checks things and tells us if something’s not right. This helps companies catch issues early and fix them before they become big problems. Plus, AI is very accurate, so it reduces mistakes and makes inspections more reliable.

By using AI, industrial inspection becomes more precise, efficient, and reliable. It’s like having a superhero assistant that helps us keep things safe and working smoothly.

The AI Advantage: Transforming Industrial Inspection for the Better

In an age where accuracy and efficiency drive the success of industries, the introduction of AI in inspections has truly been a game-changer. Harnessing the power of technology not only streamlines the process but also offers unparalleled precision, reducing human error and enhancing the overall quality of inspections. Industrial assets, being vital to business operations, deserve nothing but the best when it comes to maintenance and inspection.

Enhanced Analysis of Footage: AI can analyze vast amounts of video data from drones and ROVs, pinpointing defects and anomalies with greater precision than manual reviews.

Rapid Data Processing: Even large sets of footage can be quickly processed by AI, accelerating the inspection timeline.

Reduced Human Bias and Error: AI eliminates the potential for human oversight or bias in analyzing video data, ensuring consistent results.

In-depth Insights: AI can categorize and provide severity metrics for detected issues, offering deeper insights into the condition of assets.

Efficient Data Management: AI can automatically categorize, label, and store footage for easy future access and comparative analyses.

Adaptive Learning: As more footage is analyzed, the AI model can continuously learn and improve its detection capabilities.

Safer Inspections: While drones and ROVs can access hard-to-reach areas, AI ensures that every frame of their footage is meticulously analyzed for defects.

Cost-effective: Detailed analysis of every second of footage might be prohibitive manually due to time and labor costs. AI can perform this at a fraction of the cost.

Detailed Reporting: AI can automatically generate comprehensive reports from analyzed footage, highlighting key areas of concern and providing actionable insights.

Future Compatibility: As drone and ROV technologies evolve, capturing more detailed or varied footage, AI can be adapted to analyze the new data formats effectively.

If you’re looking to modernize your inspection processes and embrace the future today, reach out to our team at Kopterflug. We’re committed to helping you transform your inspections with the power of AI.

Request a Quote

Frequently Asked Questions

Our Inspection Experts

CEO

CEO & Founder

Philipp

CFO & co-owner

Stephan

Operations

Juliana

Maritime Specialist