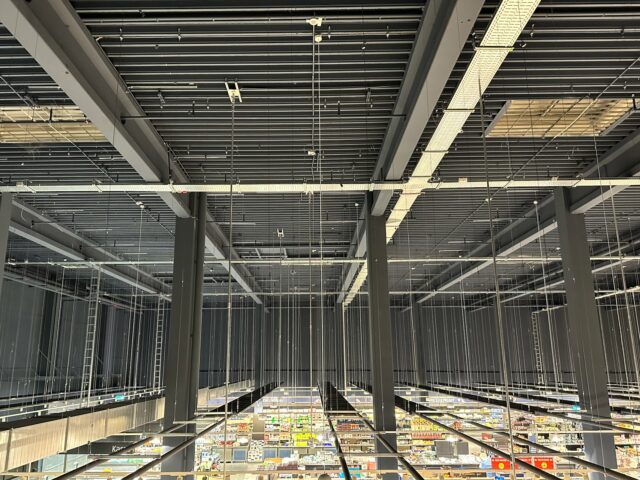

Inspection of hard to reach sprinkler heads

- Efficiency and Speed: Drone inspections swiftly assess sprinkler heads without scaffolding or site shutdowns, ensuring minimal disruption and rapid data collection.

- Cost-Effectiveness: Drone and camera inspections provide accurate results at a fraction of the cost of traditional methods, eliminating expenses related to scaffolding and operational downtime.

- Enhanced Safety: By removing the need for workers to navigate heights and hazardous areas, drone inspections prioritize safety and mitigate risks during sprinkler head assessments.

Mastering the Unreachable: Innovations for Sprinkler Head Inspections

In modern sprinkler systems, the piping networks are equipped with sealed nozzles that individually open and spray extinguishing water onto the source of fire when they are heated. They combat or extinguish the fire directly at its source through the cooling effect of water evaporation and the subsequent air sealing achieved by wetting the area. A fire extinguishing process is triggered by a temperature increase at the sprinkler head. This is accomplished either by the expansion of a liquid or by breaking a soldered connection. The sensitivity of activation can be influenced by the design of the sprinkler. A comprehensive piping network with closed fire nozzles safeguards the designated areas. To ensure an adequate water supply, various combinations of compressed air water containers, elevated reservoirs, municipal water, supply or intermediate tanks with pumping systems, or a combination thereof, can be used. The effectiveness of a sprinkler system is designed based on the categorization of fire hazards (Low Hazard LH, Ordinary Hazard OH1 to 4, High Hazard Production HHP1 to 4, and Storage HHS1 to 4). The key parameters crucial for system dimensioning include the protected area, water application rate, effective coverage area, and operating time.

In the dynamic landscape of modern technology, the realm of sprinkler head inspections is undergoing a transformative shift. With the advent of innovative solutions, the challenges posed by hard-to-reach sprinkler heads are being addressed head-on. “Mastering the Unreachable: Innovations for Sprinkler Head Inspections” delves into the exciting world of advancements that are reshaping inspection methodologies. This paradigm shift is driven by a synergy of indoor drones and specialized cameras, enabling access to areas that were once considered nearly impossible to assess comprehensively. From the intricate spaces within structures to elevated corners, these cutting-edge tools are revolutionizing how we inspect sprinkler heads. This article uncovers the potential of these innovations to redefine safety, efficiency, and accuracy in sprinkler system maintenance, paving the way for a more secure and reliable future.

- Efficiency and Speed: By employing drones and advanced cameras, inspections become faster and more efficient. Drones can navigate intricate spaces quickly, capturing high-resolution imagery in a fraction of the time traditional methods would require. This efficiency leads to minimal disruption and reduced downtime, allowing operations to resume swiftly.

- Comprehensive Assessment: Indoor drones equipped with specialized cameras provide unparalleled access to inaccessible areas. They can capture detailed images and data from various angles, ensuring a thorough evaluation of sprinkler heads that might have been overlooked using conventional methods. This comprehensive assessment minimizes the risk of unnoticed issues.

- Enhanced Safety and Cost Savings: The technology eliminates the need for erecting scaffolding or interrupting facility operations, significantly reducing safety risks for workers. Additionally, the cost savings are substantial – drone and camera inspections eliminate expenses related to scaffolding setup, labor, and operational downtime, making it a more cost-effective approach in the long run.

From Corrosion to Misalignment: Understanding Sprinkler Head Compromises

Sprinkler heads can experience various defects that can compromise their functionality and effectiveness. Some common defects include:

Clogging: Accumulation of debris, dirt, or sediment can lead to clogged nozzles, affecting water distribution and coverage.

Corrosion: Over time, exposure to moisture and environmental factors can cause rust and corrosion on the sprinkler head’s components, impacting its performance.

Mechanical Damage: Physical impact or mishandling can result in bent, broken, or misaligned components, hindering proper water distribution.

Leakage: Faulty seals, gaskets, or connections can cause water leakage around the base of the sprinkler head, wasting water and potentially damaging surrounding areas.

Wear and Tear: Regular use and exposure to changing weather conditions can lead to wear and tear, causing deterioration of the sprinkler head’s materials and affecting its lifespan.

Inconsistent Spray Pattern: Issues with the nozzle or pressure regulation can cause uneven water distribution, resulting in dry spots or overwatered areas.

Freezing Damage: Water left inside the sprinkler system during freezing temperatures can expand and damage components, leading to cracks and leaks.

Improper Installation: Incorrect installation can result in misaligned or tilted sprinkler heads, affecting their coverage area and water distribution.

Age-related Degradation: Sprinkler heads have a finite lifespan, and as they age, their components can degrade, leading to reduced efficiency and effectiveness.

Vandalism: Intentional tampering or vandalism can lead to damage or misalignment of sprinkler heads, impacting their performance.

Fire Safety Priority: Why Sprinkler System Maintenance Matters

Regular maintenance of sprinkler systems is crucial to ensure their proper functioning in case of emergencies. Here are some reasons why maintenance of sprinkler systems is so important:

Reliability: Sprinkler systems are intricate setups with various components such as pipes, sprinkler heads, valves, and pumps. Maintenance ensures that all these parts are in good working condition and can be activated when needed.

Early Problem Detection: During maintenance, potential issues or defects can be identified before they escalate into significant problems. This helps prevent costly repairs or failures.

Preventing Clogging: Over time, sprinkler heads can become clogged due to debris, rust, or water deposits. Regular maintenance ensures that sprinkler heads are clear of obstructions and function efficiently.

Safety: A properly maintained sprinkler system can save lives and limit property damage. During a fire, swift and reliable intervention is critical, and malfunctioning sprinklers could be life-threatening.

Compliance: Many countries and regions require regular inspections and maintenance of sprinkler systems by law. Non-compliance can lead to legal consequences.

Insurance Requirements: Insurance companies often demand that sprinkler systems be regularly maintained to keep insurance coverage valid. Neglected fire protection could result in claims not being covered.

Long-Term Efficiency: Regular maintenance can extend the lifespan of a sprinkler system. Well-maintained systems operate more efficiently and exhibit higher reliability.

In summary, maintaining sprinkler systems is essential to ensure their functionality, efficiency, and dependability. It contributes to protecting lives, minimizing property damage, and upholding fire safety within a building.

Precision in Flight: How Drones and Cameras Elevate Sprinkler System Assessments

Inspecting hard-to-reach sprinkler heads using drones and cameras offers a range of significant benefits. This innovative method effectively addresses challenges posed by the location of sprinkler heads in high ceilings or tight spaces. Drones and cameras provide precise and detailed visual inspections without inspectors needing physical access to these inaccessible areas. This results in increased safety for inspectors by eliminating hazardous conditions associated with climbing or using aerial lifts.

Furthermore, drone-based inspections notably minimize facility downtime. Unlike traditional methods, setting up aerial lifts or scaffolding often requires significant time and preparation, leading to extended operational interruptions. Drones, on the other hand, can be quickly deployed and operated, resulting in minimal disruptions to ongoing operations. This approach optimizes inspection processes and ensures seamless continuation of daily activities.

The fusion of drones and high-resolution cameras enables a thorough examination of sprinkler heads, capturing even the smallest details. This visual precision aids inspectors in identifying defects, corrosion, or other anomalies that could compromise proper functioning. Additionally, documentation through high-quality images and videos preserves the condition of sprinkler heads for reporting, analysis, and comparative purposes.

Overall, drones and cameras offer an innovative solution for inspecting hard-to-reach sprinkler heads that not only enhances safety and efficiency but also leads to reduced operational disruptions and accurate documentation. This contributes to optimized maintenance of fire protection systems and the safety of buildings and individuals.

Request a Quote

Frequently Asked Questions

Our Inspection Experts

CEO

CEO & Founder

Philipp

CFO & co-owner

Stephan

Operations

Juliana

Maritime Specialist